In the early days of the Discovery Collector, the installation process was both complicated and, at times, frustrating. After physically measuring the dimensions of the barn area to be cleaned, a technician had to manually create a map within the machine’s control board. This required meticulously entering each measurement into the programming application. Only once the map was built could the actual route programming begin. This process alone took many hours.

Programming itself was a time-consuming and delicate task. The technician, connected directly to the machine on farm, had to input each directional command sequentially to ensure the entire area was covered by physically walking behind the machine as it maneuvered through the barn. Every route had to start and end at the charger, and the Collector would drive each step in real time as it was being programmed. Careful attention was required to keep the total route length within a specific limit to maintain the proper ratio between the machine’s charge capacity and the required driving distance. If a route became too long—or if even a single error was made—the entire process needed to be restarted from the beginning.

After programming was completed, each route had to be tested, and any necessary adjustments required starting the process again from scratch. For larger barns utilizing multiple Discovery Collectors, this entire sequence had to be repeated for every single machine.

Thankfully, for the sanity of our technicians and the costs to our producers, we’ve made huge progress in this process in the last year.

With the introduction of modern back-end technologies such as the Route Assistant application and our recent investment in a LIDAR Scanner, scanning, installing, and programming a Discovery Collector has never been easier. Using the LIDAR scanner, the technician simply walks through the barn while the device generates a point cloud map that is automatically converted into a full 3D model. From that model, an accurate 2D floorplan of the barn is produced—transforming a process that once took hours into one that can be completed quickly and with far greater precision.

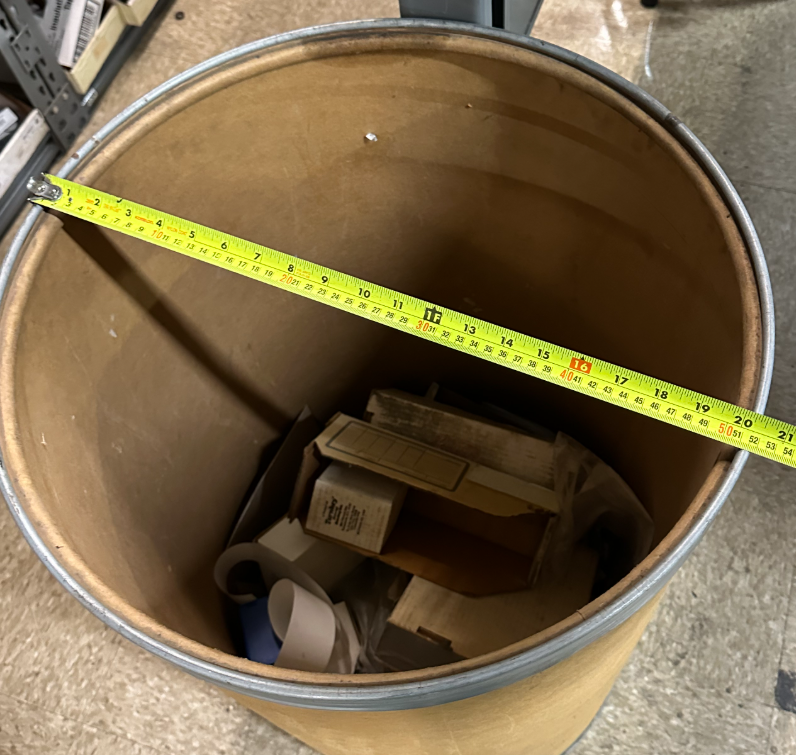

To practice using the machine and put it to the test, I scanned part of our Leola warehouse, uploaded the image into the LIDAR software and used the program to measure the diameter of the trash can- 52 centimeters. A perfect match to what I measured the diameter to be in real life.

The 2D floorplan is then imported into the Route Assistant application, which is used to build the “map” of the barn and design all necessary routes. Routes can be created remotely with real-time visualizations of the cleaning paths and dynamically updated estimates of the expected cleaning time. Because of these tools, most issues are resolved before physical testing even begins.

Once the routes are complete, the route package is installed on the machine for testing. Any adjustments that need to be made by the technician can be implemented either on-farm by the technician or remotely by the customer using a route package that can be sent via email. Updated route packages can be sent directly to the machine with ease using the Lely Control Plus application. That means if a customer wants a change to the route, it can be done without having to make a trip out to the farm, resulting in major cost savings for the customer.

The combination of the Route Assistant and LIDAR scanning has become invaluable in building routes and implementing efficient, optimized cleaning plans for any required barn layout. We look forward to utilizing this tool to lower the cost of entry for customers interested in collectors and are excited about the possibilities of utilizing this tool in other applications.