Milk price is top of mind for everyone right now. It’s hard to have a conversation in the dairy industry without it coming up. With margins under pressure, we’re hearing more producers question whether they can afford routine robot maintenance.

Our response is simple: can you afford not to?

When milk prices drop, it’s common to see maintenance pushed out or reduced. On the surface, that can feel like a reasonable way to protect cash flow. The challenge is that delaying planned maintenance often leads to more after-hours emergency calls—calls that happen when something has already gone wrong and production is already being impacted.

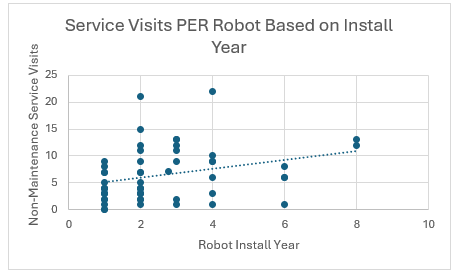

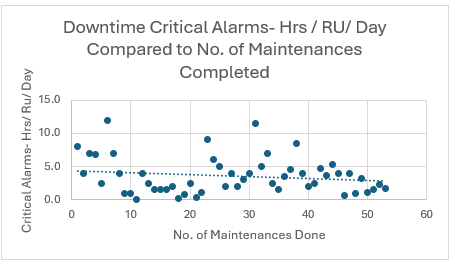

We regularly review performance trends across our customer base to better understand what drives reliable robot performance. Year after year, the strongest correlation with higher annual uptime is newer equipment—which is no surprise. The second strongest correlation is allowing maintenance to be completed to our full standard and on a recommended schedule.

This year, we compared two general approaches to maintenance. One group of customers manages most of their own robot maintenance. They decide when maintenance is performed, which parts are replaced, and how involved our team is. Another group allows our team to oversee and perform maintenance on a consistent, proactive schedule.

What we consistently see is this: customers who handle their own maintenance tend to experience more emergency service events. While planned maintenance may appear lower in the short term, emergency calls introduce variability and risk. It often takes just one unexpected failure to disrupt routines, increase stress, and impact production.

That increased risk shows up clearly in uptime. Customers who primarily managed their own maintenance averaged 98.09% uptime over the course of the year. Customers who followed a proactive, scheduled maintenance approach averaged 99.52% uptime.

That difference—1.43 percentage points—may not sound large, but over a full year it translates to 5.22 additional days of production per robot.

When you convert uptime into milk in the tank, the value of consistency becomes clear. Several additional days of production—especially during tight margin years—can quickly outweigh the perceived savings of deferring planned maintenance. The real benefit isn’t just fewer repairs, but greater predictability and fewer disruptions to daily routines.

We understand the pressure low milk prices put on cash flow, and the need to be thoughtful about where every dollar goes. Planned maintenance can feel like an easy place to cut in the short term. Our experience shows that those short-term savings often come with higher risk and greater losses down the road.

The question we encourage every producer to ask isn’t “How can I spend less on maintenance this year?” but rather:

How do I protect uptime and production when margins matter most?