Last month, we hosted our annual customer training event, and it was packed with valuable insights. If you couldn’t make it, here’s what you missed!

Jakob Vogel from Lely North America traveled from Canada to share his expertise on optimizing farm finances through hoof health. One key takeaway was that it costs just as much to do a good job as it does a bad job—so why not strive for excellence? He emphasized the importance of viewing and discussing the farm as a business, highlighting that more milk production doesn’t always mean increased profitability. Feed costs remain a hot topic, as they are the largest expense on a farm, yet hoof health is often overlooked. To maximize profitability, farmers should focus on controlling what they can and not stress over uncontrollable factors.

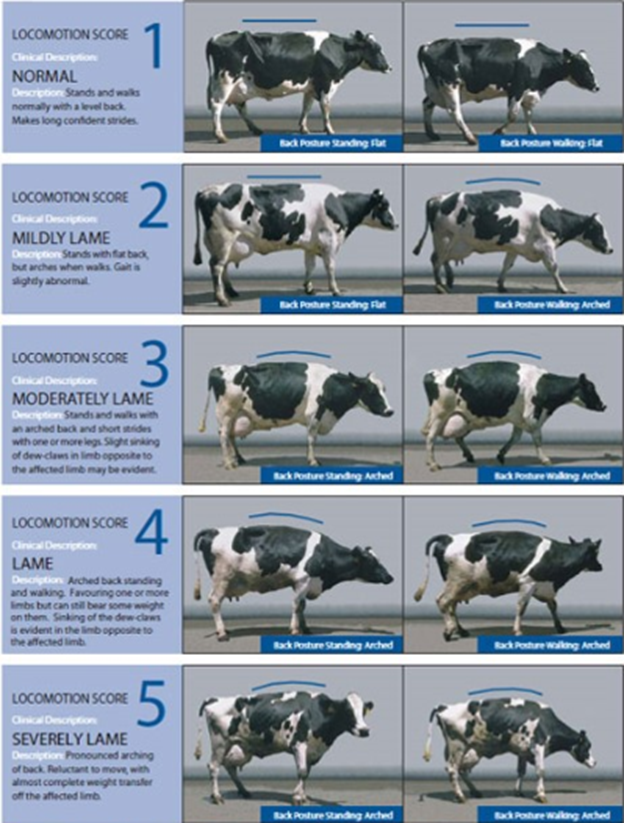

Jakob also stressed the importance of hoof health monitoring. Farmers should regularly review their hoof trimmers’ reports and input data into Horizon to set hoof health goals. He introduced the lameness scorecard, noting that consultants are statistically better at identifying lame cows due to their training, fresh perspective, and ability to dedicate time to observing the herd. A significant statistic he shared is that a cow with a lameness score of 2 (on a scale from 1 to 5) already experiences a 2% milk loss.

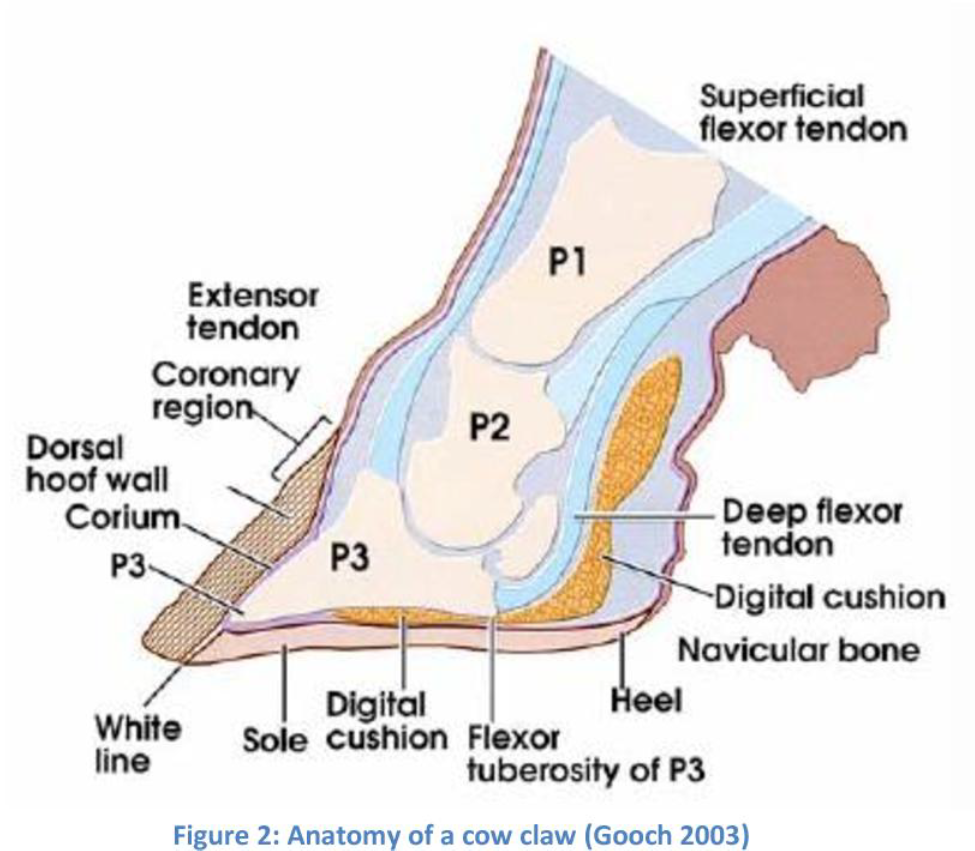

Understanding the differences between ulcers and abscesses is critical. Ulcers, which are not related to nutrition, typically result from poor barn cleanliness. The bacteria that cause digital dermatitis, called spirochetes, are naturally present in cow manure, meaning even closed herds are at risk. Abscesses, on the other hand, occur at the hoof’s edges and can be caused by rations that are too “hot.” Ulcers develop in the middle of the hoof at the P3 bone region. Beneath this bone lies a fat pad, which thins when cows lose weight, increasing pressure on the sole and leading to ulcers. Cows that lose more than half a body condition score in the first 60 days of lactation face a significant impact on lameness. This is another reason why dry cow pens should not be overcrowded. Additionally, as cows approach calving, oxytocin loosens their ligaments, increasing pressure on their soles and exacerbating lameness.

Lameness also carries a financial burden. According to a 2023 study, the average lame cow costs $336.91 annually due to milk losses of approximately 800 pounds (5.5 lbs/day). These cows remain open for an extra 28 days and are nine times more likely to require additional breedings. With an industry-wide lameness rate of 26%, a 100-cow herd could lose $6,115 per year. In robotic milking systems, lame cows are 2.2 times more likely to become fetch cows, reducing their daily milkings by 0.3. On average, lame cows produce 3.5 pounds less milk per day. In a 100-cow herd with a 26% lameness rate, that equates to 33,215 pounds of lost milk annually. At a milk price of $21.71 per hundredweight, this results in a staggering $7,210.97 in lost revenue.

So, what can farmers do? The key is proactive monitoring. Reviewing hoof trimmers’ reports and entering data into Horizon allows for better management. Farmers should utilize FMS support when needed and implement regular foot baths—whatever schedule is necessary to control digital dermatitis. Horizon reports can also help identify cows for hoof trimming, ensuring the entire herd gets trimmed twice per lactation. Evaluating the hoof trimmer’s qualifications is crucial; formal training, proper tools, and trimming techniques all impact hoof health. Additionally, maintaining a clean, dry, well-ventilated, and uncrowded environment is essential. Farmers should also ensure cows maintain the proper body condition score for their lactation stage and that their diet doesn’t induce acidosis. By treating the treatable and controlling the controllable, farms can significantly improve hoof health and profitability.

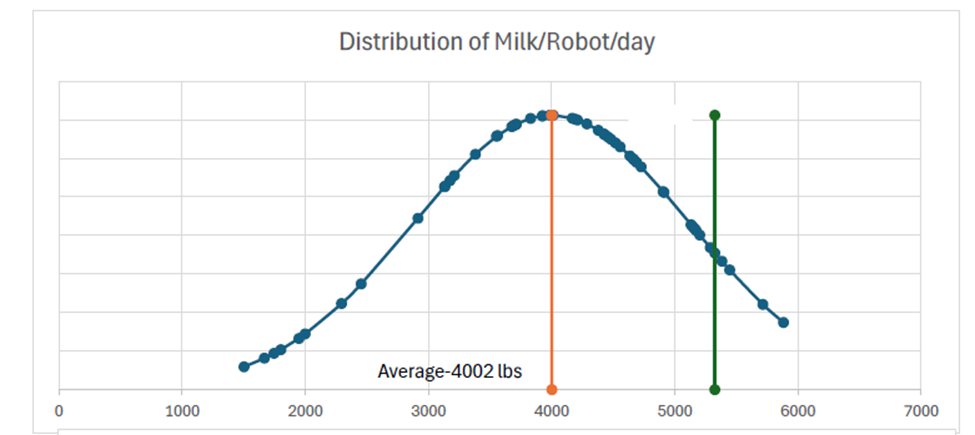

If that wasn’t enough, this was just the first presentation of the day! FMS Specialist Kayla Brody followed with an in-depth look at the latest Horizon updates and her unique comparison scorecard. She has developed distribution graphs for different KPIs, allowing customers to see where they stand compared to others in our Lely Center. If you missed the meeting and want a copy, be sure to reach out to her!

Cortney Beakler wrapped up the day with a hands-on troubleshooting session for robots. She covered the different CANBUS networks for each robot type, how to read alarms, and the critical information technicians need to efficiently troubleshoot issues over the phone. After lunch, customers participated in interactive workshops where they disassembled and rebuilt key robot components. Hands-on experience included working with rope cylinders, MQCC2 (somatic cell sampler), CANBUS network parts for the A5, as well as water and vacuum valves for A4s and A5s.

There’s no doubt that attendees left the meeting with valuable knowledge and practical skills to enhance their farm’s profitability. If you missed out this time, we hope to see you at our next event!