In April, I was able to attend the Level 2 Vector Analyse and Optimise training in Ottawa, Ontario. Through this training, we learned how to take a deeper look into utilizing the Lely Technician Diagnostic Assistant (LTDA) and how to better help our Vector customers in optimizing and troubleshooting the system. Here are some key things I took away from the training.

Minimum Load Setting – This setting is most useful to improve mixing quality of fences which receive a small amount. The recommendation is to set the minimum load on the Vector so that the feed covers the top of the auger, at a minimum. Because this setting is usually used on small loads, it is most commonly used with heifer groups. The advised minimum load depends on the dry matter percentage in the set ration and shouldn’t exceed your maximum load or maximum dosing weight. This feature will postpone feeding until additional fences with the same ration can be combined and minimum load attained; therefore, it’s beneficial in helping to ensure proper mix quality and creates a more efficient system.

Mixing Quality:

The easiest way to remember proper settings for the best mix quality is: Long before short, dry before wet!

We’re typically aiming for dry matter in rations to be between 40% to 50%. You want the smallest inclusion ingredients closest to the MFR load point; that will give you the highest accuracy for those set ingredients. Farms using a conveyor system want the shortest possible length to allow for clean-off time and the most accurate feed amounts.

Another key factor to mix quality is the sharpness of the knives. It is recommended to replace the knives in the Vector once a year, depending on the ration.

Loading Order:

The advised max load for the Vector is 1,322 pounds, or about 8 inches from the top of the MFR rim. The recommended chop length for hay is 1–1.5 inches, whereas straw is 2–3 inches. It’s crucial that these ingredients aren’t cut too long. Ingredients that are too long cause increased sorting at the bunk and reduce feed intake. This also saves mixing time in the MFR and creates more efficiency in the Vector system.

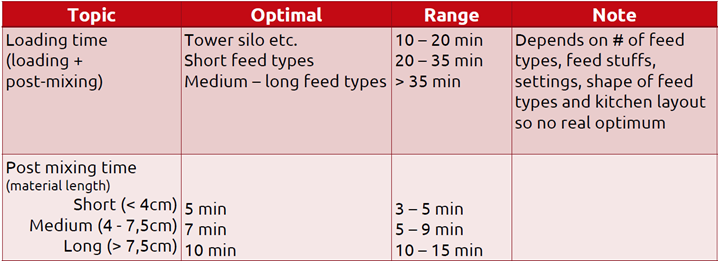

Averages for loading and mixing times:

How we utilize LTDA- Lely Technician Diagnostic Assistant:

Farm Management Support Specialists have access to Lely’s LTDA, where we can proactively analyze customers’ Vector systems and look for opportunities for improvement. We start by analyzing what alarms customers may be incurring. When did alarms occur? For how long did they occur? Where did they occur? Are the alarms critical or noncritical? This helps both the service techs and FMS diagnose and fix problems.

Every time the PDB and MFR perform a task (scanning, loading, feeding, etc), we can see detailed information for each ingredient and ration. Analyzing this information helps us improve the efficiency of the whole system. On LTDA, we can see driving time, scanning times, waiting, out of operation, and loading. Within each batch, we can see detailed insights, like how much was requested versus how much was actually loaded, and the difference between the two. This helps us determine the accuracy of an entire load and within each ingredient.

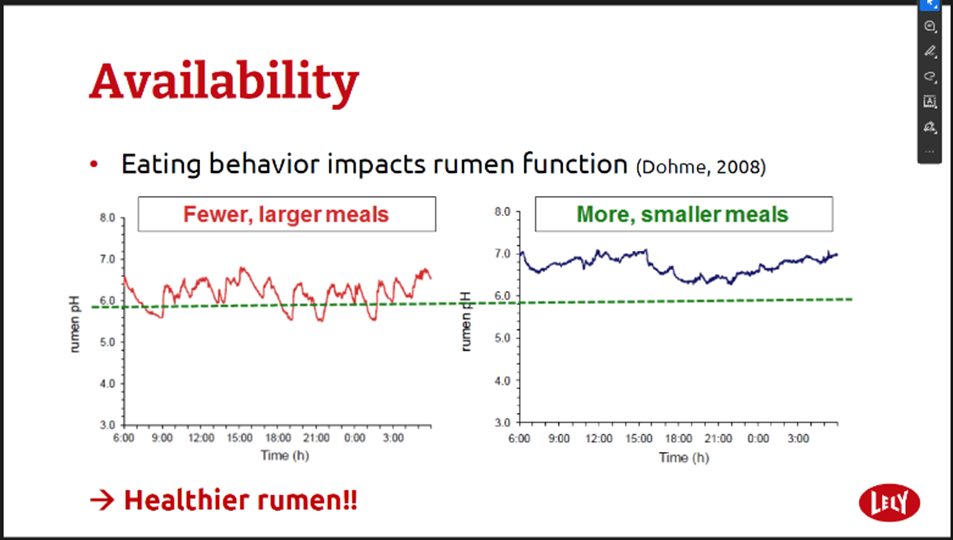

We can also analyze the day rhythm of each feed fence—how often the Vector is feeding the fence throughout the day versus night, as well as look at feed heights and fence pauses. For example, when hot weather hits, we often see the Vector feed less during the day and more at night when it cools down and cows’ intake increases at the bunk. The Vector allows cows to feed on smaller meals more frequently throughout the day. Research has been done to show that this has many positive effects on rumen function.

As Lely owners know, having any piece of equipment requires maintenance. Making sure you’re doing owner’s maintenance on your Vector will help keep it running to its full potential. Below you will find the owner’s maintenance sheet for your Vector. If you would like a hard copy, contact your Farm Management Support Advisor!

A Vector system is highly customizable to your operation and the way you want to feed your cows. To ensure your Vector is feeding cows to meet their fullest potential, be sure to utilize your FMS specialist and gain insights from the LTDA tool.